Project Timeline: Q2 2023 – Q1 2024

Project Budget: USD 122,000

Objective: Ensure compliance with insurance policy requirements and enhance fire safety

Situation:

The existing fire water system at the Injection Molding Plant required an upgrade to meet insurance policy requirements. The outdated system posed risks to safety, compliance, and operational continuity, making modernization essential to ensure reliable fire protection measures.

Task:

The project aimed to:

✅ Upgrade the fire water piping system for improved coverage and efficiency

✅ Ensure compliance with insurance and fire safety regulations

✅ Minimize fire hazards and enhance workplace safety

✅ Complete the project within the USD 122,000 budget and planned timeline

Action:

🔍 System Assessment – Evaluated fire water distribution and compliance gaps

🚧 Piping Upgrade – Replaced and optimized the network for better water flow

📑 Regulatory Coordination – Worked with insurance and safety teams for compliance alignment

📊 Risk Mitigation – Ensured reliable fire protection without disrupting operations

💰 Budget Management – Controlled costs while meeting safety and efficiency targets

Result:

🔥 Enhanced Fire Safety – Improved fire water distribution and protection coverage

✅ Full Compliance Achieved – Met insurance policy and regulatory standards

⚙️ Operational Reliability – Minimized risks and ensured a more efficient system

💲 On-Time & Within Budget – Completed successfully while optimizing resources

The project strengthened plant safety, reduced fire risks, and ensured continued compliance with industry standards. 🔧🚀

Click to see Project details

📅 Project Timeline: Q2 2023 – Q1 2024

💰 Project Budget: USD 122,000

🎯 Objective: Ensure compliance with insurance policy requirements and enhance fire safety

Objective:

This project focused on upgrading the fire water system at the Injection Molding Plant to meet insurance policy requirements and improve fire safety. The previous system had outdated components, posing risks to safety, compliance, and operational continuity.

By enhancing the fire water piping network, the plant achieved better fire protection coverage, regulatory compliance, and increased workplace safety, ensuring a more reliable and efficient fire suppression system.

Upgrade Details:

The project involved strategic improvements to modernize fire safety infrastructure, including:

🔍 System Assessment & Compliance Review – Evaluated fire water distribution, pressure requirements, and regulatory gaps.

🚧 Piping Network Upgrade – Replaced outdated pipes and optimized flow paths for improved water distribution.

📑 Regulatory & Insurance Coordination – Worked closely with insurance and safety authorities to ensure full compliance.

📊 Risk Mitigation & Operational Safety – Upgraded system reliability while minimizing disruption to plant operations.

💰 Cost Optimization & Resource Allocation – Controlled expenses while achieving maximum impact within budget.

Unlike a complete system overhaul, the upgrade focused on targeted enhancements to improve performance while staying within the allocated budget.

Compliance & Safety:

The fire water system upgrade ensures alignment with fire safety regulations and insurance policy standards, delivering key benefits:

✅ Regulatory Compliance – Fully meets fire safety and insurance policy requirements.

🔥 Improved Fire Protection – Ensures adequate water flow and coverage in case of emergencies.

👷♂️ Enhanced Workplace Safety – Reduces fire hazards and improves response capability.

⚙️ Operational Continuity – Prevents downtime due to non-compliance or safety risks.

Operational Impact:

The upgraded fire water system provides significant advantages in safety, reliability, and efficiency:

🔥 Enhanced Fire Safety – Upgraded piping ensures better water flow and coverage in high-risk areas.

✅ Full Compliance Achieved – Meets insurance and fire safety standards, reducing compliance risks.

⚙️ Operational Reliability – Improves system performance, ensuring immediate response capability.

💲 On-Time & Within Budget – Efficient execution while maximizing safety impact.

Budget Management & Execution Strategy:

The project was successfully executed within the USD 122,000 budget through efficient planning:

💰 Strategic Procurement – Sourced high-quality materials to ensure long-term reliability.

🛠 Phased Implementation – Minimized plant disruption while upgrading key sections.

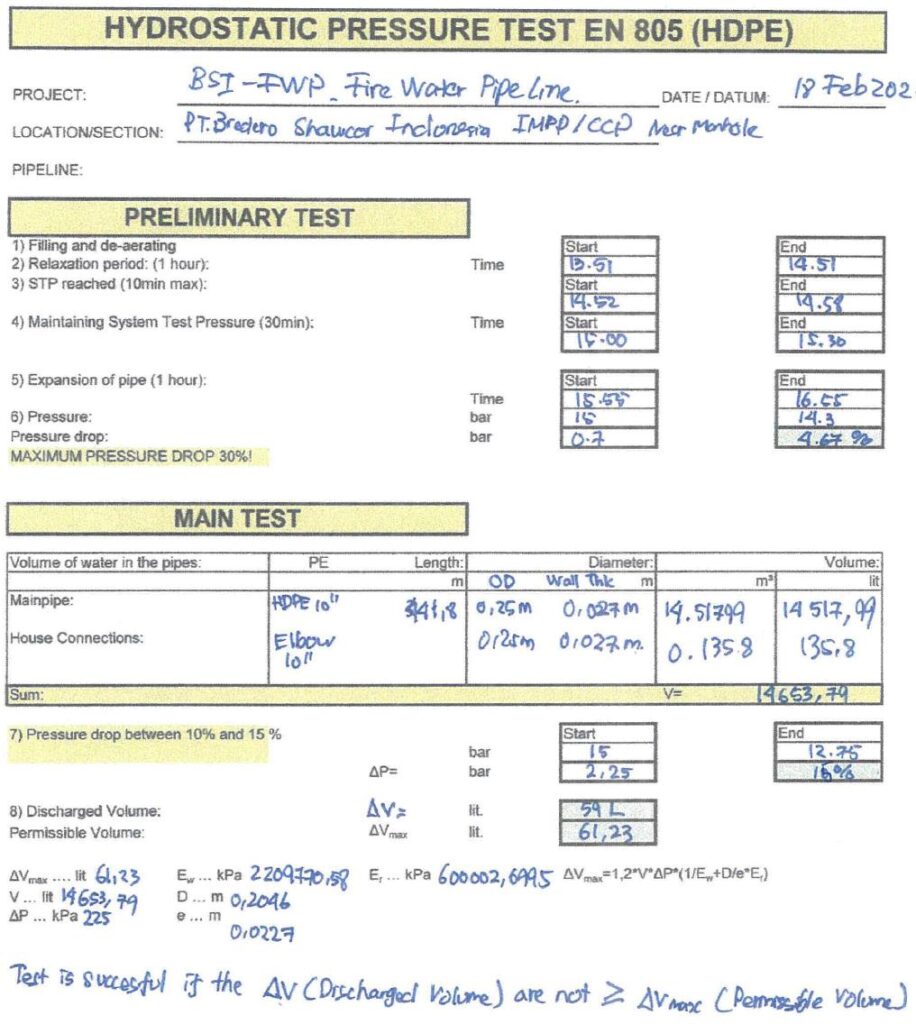

📊 Performance Testing & Compliance Verification – Conducted rigorous checks to ensure system effectiveness.

By prioritizing cost-effective solutions, the project optimized resources while enhancing fire safety infrastructure.

Conclusion:

The Injection Molding Plant Fire Water System Upgrade successfully improved fire safety, compliance, and operational reliability. Through targeted piping enhancements and system optimization, the project delivered a safer, more efficient, and regulation-compliant fire suppression system.

This upgrade strengthens the plant’s long-term safety strategy, ensuring better fire protection and compliance with industry standards.

🔧 Project Successfully Implemented – Strengthening Fire Safety & Compliance! 🚀