📅 Timeline: Q1 2024 – Q3 2024

💰 Budget: USD 120,000

🎯 Objective: Replace and refurbish corroded pipelines to ensure system reliability and prevent water loss

Situation:

Corrosion and leakage in the freshwater supply pipelines caused water loss and operational risks. To maintain system integrity, a CAPEX project was launched to replace severely damaged pipelines and refurbish others, ensuring long-term reliability.

Task:

✅ Assess & Identify corroded pipelines (above & underground)

✅ Replace & Refurbish critical sections with corrosion-resistant materials

✅ Ensure Seamless Integration into the existing water network

✅ Conduct Testing & Quality Checks for compliance & performance

✅ Complete the project within the USD 120,000 budget

Action:

🔍 Inspection & Risk Analysis – Mapped pipeline vulnerabilities

🔧 Targeted Replacements & Repairs – Upgraded key sections for durability

🔄 System Integration – Ensured minimal disruptions to water supply

📊 Testing & Validation – Leak & pressure tests for performance assurance

💰 Budget Optimization – Delivered cost-effective execution

Result:

✅ Eliminated Water Loss & Leakage – Improved supply efficiency

✅ Enhanced System Reliability – Reduced maintenance & future failures

✅ Regulatory Compliance – Verified pipeline integrity

✅ On-Time & Within Budget – Efficient execution with no overruns

This strategic upgrade strengthened water infrastructure, ensuring operational efficiency, cost savings, and long-term sustainability. 💧🔩

Click to see Project details

📅 Project Timeline: Q1 2024 – Q3 2024

💰 Project Budget: USD 120,000

🎯 Objective: Replace and refurbish corroded freshwater pipelines to ensure system reliability and prevent water loss

Objective:

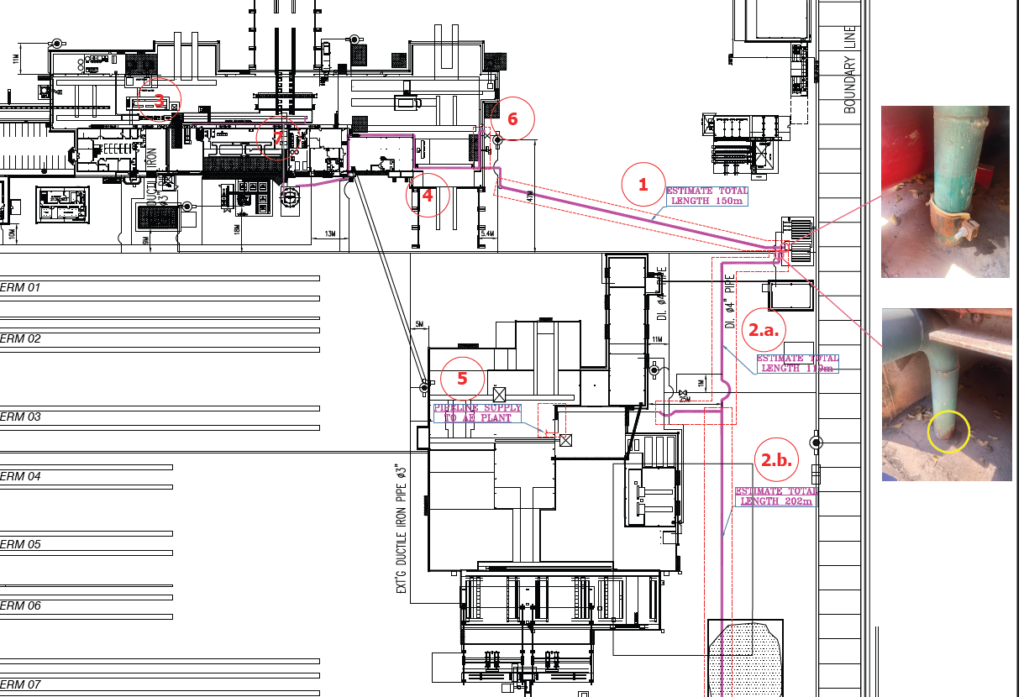

This CAPEX project was launched to address corrosion and leakage issues in the freshwater supply system. The existing pipeline network, both underground and aboveground, had suffered from severe wear, leading to operational risks, water loss, and potential supply failures.

By replacing severely corroded pipelines and refurbishing repairable sections, the project aimed to enhance system reliability, optimize resource utilization, and ensure long-term infrastructure sustainability while maintaining uninterrupted operations.

Replacement & Infrastructure Upgrades:

The project focused on the following key engineering upgrades:

🔍 Pipeline Assessment & Risk Analysis – Inspected the entire system to identify critical failure points.

🔧 Targeted Pipeline Replacement & Refurbishment – Upgraded compromised sections using corrosion-resistant materials.

🔄 Seamless System Integration – Ensured minimal disruptions while connecting new pipelines to the existing network.

📊 Rigorous Testing & Validation – Conducted leak detection and pressure tests to meet performance and safety standards.

💰 Budget-Optimized Execution – Managed procurement and resource allocation efficiently to stay within the USD 120,000 budget.

This strategic replacement and repair approach maximized system reliability while minimizing costs and downtime.

Compliance & Risk Mitigation:

The upgraded pipeline system meets all regulatory and operational standards:

✅ Regulatory Compliance – Fully adheres to industry safety and environmental regulations.

💧 Water Loss Prevention – Eliminates leakage risks, ensuring efficient water distribution.

🔄 System Reliability Enhancement – Reduces future failures and maintenance costs.

🌱 Sustainable Infrastructure – Future-proofed the water supply system with durable, corrosion-resistant materials.

Operational Impact:

The project delivered significant operational improvements, ensuring efficient and safe water supply:

🚀 Enhanced Supply Reliability – Eliminated water loss and ensured consistent distribution.

📉 Reduced Maintenance Costs – Minimized frequent repairs and emergency interventions.

🔄 Optimized Water Usage – Prevented unnecessary resource wastage.

📈 Increased Infrastructure Lifespan – Strengthened the pipeline network for long-term performance.

Budget Management & Execution Strategy:

To ensure cost-effective implementation and project success, the following measures were taken:

🛠 Optimized Material Procurement – Selected high-quality yet cost-efficient corrosion-resistant materials.

📊 Strategic Engineering Execution – Phased installation plan to minimize disruptions.

🔍 Quality Control & Testing – Rigorous validation before commissioning to ensure reliability.

With no budget overruns, the project was completed efficiently while maintaining financial discipline.

Conclusion:

The Freshwater Pipeline Replacement & Refurbishment project successfully improved water infrastructure reliability, reduced losses, and ensured compliance with safety standards. By eliminating leaks, preventing future failures, and optimizing budget execution, this CAPEX initiative reinforced the company’s commitment to sustainability, operational efficiency, and long-term infrastructure resilience. 💧🔧