📅 Project Timeline: Q1 2024 – Q2 2025 (Ongoing, 62% Completed)

💰 Project Value: USD 350,000

🎯 Objective: Develop a settlement pit for iron ore and concrete waste, ensuring effective stormwater treatment, regulatory compliance, and environmental protection.

📌 Situation:

The facility faced challenges in managing iron ore and concrete waste runoff, posing potential environmental risks and non-compliance with stormwater treatment regulations. A dedicated settlement pit was required to effectively control runoff, prevent contamination, and ensure adherence to environmental standards.

🎯 Task:

Design and construct a high-capacity settlement pit to:

✔ Improve stormwater management and sediment control.

✔ Ensure compliance with environmental regulations related to industrial waste treatment.

✔ Minimize operational disruptions while maintaining cost efficiency.

⚙ Action:

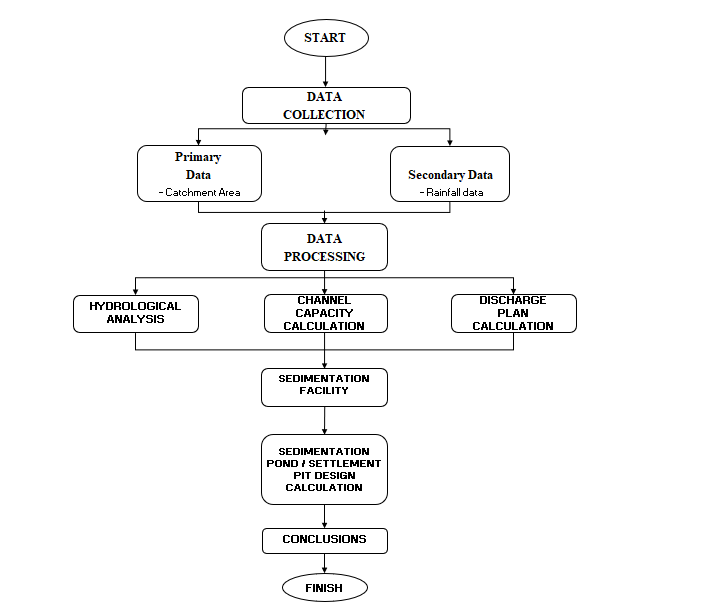

✔ Conducted Hydrological Analysis, Channel Capacity Calculation, and Discharge Plan Calculation to determine the optimal settlement pit design.

✔ Applied the Rational Method for precise drainage calculations, ensuring effective water flow management.

✔ Developed a containment system to prevent leaks, manage sedimentation, and enhance overall efficiency.

✔ Collaborated with stakeholders, including environmental engineers and regulatory bodies, to ensure alignment with industry best practices.

✔ Implemented a phased execution plan to integrate construction activities with ongoing plant operations, reducing downtime.

✔ Managed budget allocation and resource planning, ensuring the project remained within its USD 350,000 budget.

🏆 Result (Ongoing, 62% Completed):

🔹 Optimized stormwater treatment, reducing environmental impact.

🔹 Improved regulatory compliance, mitigating risks of non-conformance.

🔹 Minimized operational disruptions through a structured project execution plan.

🔹 Project is on track for completion by Q2 2025, supporting the facility’s sustainability goals and long-term environmental strategy.

Some documentation of the progress.

Click to see Project details

📅 Project Timeline: Q1 2024 – Q2 2025 (Ongoing, 62% Completed)

💰 Project Value: USD 350,000

🎯 Objective: Develop a settlement pit for iron ore and concrete waste, ensuring effective stormwater treatment, regulatory compliance, and environmental protection.

🔹 Background & Objectives

Managing iron ore and concrete waste runoff is critical for environmental compliance and operational efficiency. Without proper containment, excessive runoff and sediment accumulation could lead to environmental hazards and non-compliance with regulations. This CAPEX project was initiated to:

✔ Construct a dedicated settlement pit for proper waste containment.

✔ Implement an effective stormwater treatment system to minimize contamination risks.

✔ Ensure compliance with environmental regulations and industry standards.

✔ Optimize drainage efficiency while maintaining cost-effectiveness.

🔹 Project Scope & Implementation

1️⃣ Hydrological Analysis & Drainage System Design

📊 Flow Analysis – Assessed runoff volumes and flow patterns.

🔬 Sediment Control Strategy – Designed to prevent soil and waste erosion.

🌊 Channel Capacity Calculation – Ensured sufficient drainage capacity.

2️⃣ Settlement Pit Construction & Waste Containment

🔧 Excavation & Structural Design – Engineered for durability and optimal capacity.

🛠 Water Treatment Mechanism – Implemented sedimentation processes for runoff purification.

📑 Regulatory Compliance Assessment – Ensured adherence to environmental standards.

3️⃣ Monitoring & Optimization

📊 Validation & Testing – Conducted sedimentation efficiency tests to optimize functionality.

🔹 Technical Highlights & Environmental Impact

🌍 Effective Sediment Capture – Prevents waste discharge into natural water bodies.

💧 Stormwater Treatment Efficiency – Improves water quality before release.

🏭 Minimal Operational Disruption – Designed for seamless plant integration.

🔹 Budget Management & Execution Strategy

💰 Cost-Efficient Materials & Construction – Optimized procurement to meet budget constraints.

🛠 Phased Execution Plan – Ensured uninterrupted plant operations.

📊 Risk Mitigation Strategies – Prevented construction delays and compliance risks.

🔹 Conclusion

The Iron Ore & Concrete Waste Settlement Pit CAPEX Project is a crucial step in stormwater management and environmental sustainability. By implementing hydrological analysis, drainage optimization, and real-time monitoring, this project ensures regulatory compliance and long-term environmental protection. Currently 62% completed, it is on track for Q2 2025 completion, reinforcing the company’s commitment to sustainability and operational excellence.