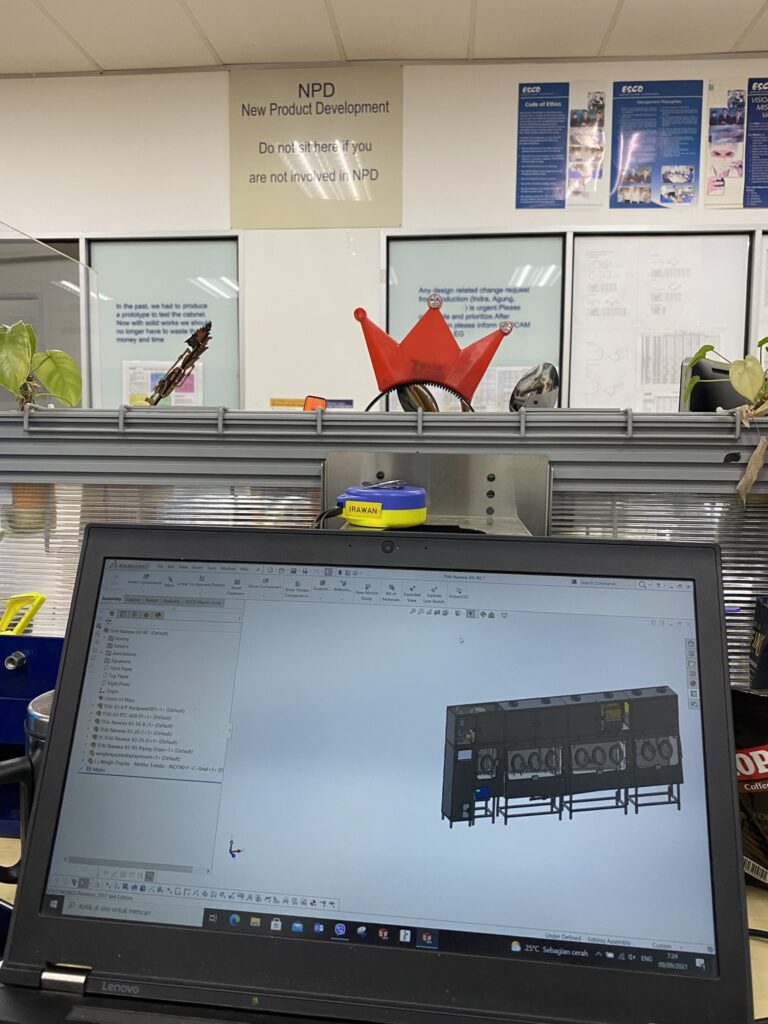

As a Mechanical Design Engineer at Esco, I played a pivotal role in the design, development, and production of high-precision Isolators, Incubators, and Biosafety Cabinets. My expertise in 3D modeling, failure analysis, process optimization, and compliance with ISO standards ensured the successful execution of projects, meeting stringent regulatory and client-specific requirements.

My project below:

🔹 2 Units of ACTI-IS-4G-1PTC(1G) | Isolated ISO Class 5 Grade A

✔ Material Selection – Defined suitable materials for durability and contamination control.

✔ DFM/DFA Optimization – Streamlined fabrication to reduce complexity and improve efficiency.

✔ Production Control – Managed laser cutting, bending, welding, assembly, and final testing.

✔ Regulatory Compliance – Ensured final products met ISO Class 5 Grade A requirements.

✔ Delivered all units on schedule and within financial constraints.

🔹 3 Units of GPPI-IS-3G-2PTC(1G) | Isolated ISO Class 5 Grade A

✔ Material Selection – Defined suitable materials for durability and contamination control.

✔ DFM/DFA Optimization – Streamlined fabrication to reduce complexity and improve efficiency.

✔ Production Control – Managed laser cutting, bending, welding, assembly, and final testing.

✔ Regulatory Compliance – Ensured final products met ISO Class 5 Grade A requirements.

✔ Delivered all units on schedule and within financial constraints.

🔹 Containment Barrier Isolator – Class III Biosafety Cabinets

✔ Material Selection – Defined suitable materials for durability and contamination control.

✔ DFM/DFA Optimization – Streamlined fabrication to reduce complexity and improve efficiency.

✔ Production Control – Managed laser cutting, bending, welding, assembly, and final testing.

✔ Leak & Pressure Testing – Ensured compliance with Class III Biosafety Cabinet standards.

✔ Delivered all units on schedule and within financial constraints.

🔹 1 Unit of HPI-3G | Class 2 Containment Enclosure

✔ Material Selection – Defined suitable materials for durability and contamination control.

✔ DFM/DFA Optimization – Streamlined fabrication to reduce complexity and improve efficiency.

✔ Production Control – Managed laser cutting, bending, welding, assembly, and final testing.

✔ Manual Pressure Leak Testing as per ISO 10648-2.

✔ Delivered all units on schedule and within financial constraints.

🔹 2 Units of TFAI-3G & 1 Unit of TFAI-4G | High-Precision Isolators

✔ Material Selection for Sealed Environments.

✔ Production Process Control – Managed cutting, forming, and joining techniques.

✔ Leakage Testing to meet ISO 14644-7 standards.

✔ Delivered products with zero delays and within the allocated budget.

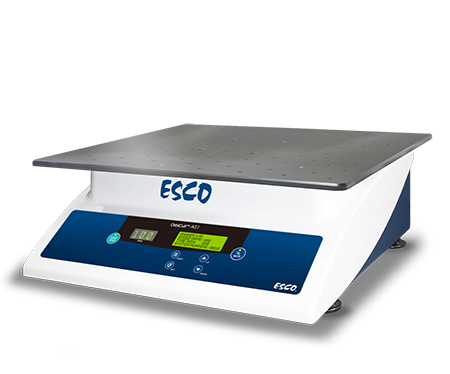

🔹 11 Units of 2D Rockers – OrbiCult™ Ambient Shaker (CO2 Resistant)

- Led the end-to-end production of CO2-resistant 2D Rockers, built to meet client-specific laboratory and research requirements.

- Selected materials for CO2 resistance and long-term reliability.

- Led fabrication, welding, and assembly coordination.

- Monitored final testing to ensure smooth functionality and compliance.

Through these projects, I have demonstrated technical expertise, leadership in high-precision manufacturing, and a commitment to engineering excellence. My ability to streamline production processes, meet complex regulatory demands, and drive cost-effective solutions ensures that every project is delivered to the highest industry standards.

🔹 Engineering Contributions & Process Improvements

✔ Material Selection & Validation – Chose optimal materials for durability, safety, and compliance.

✔ DFM/DFA Implementation – Improved manufacturability and streamlined assembly processes.

✔ Production Control & Coordination – Managed laser cutting, bending, welding, assembly, and testing for multiple projects.

✔ Process Optimization – Enhanced efficiency to reduce lead time and minimize production costs.

✔ Quality Assurance & Compliance – Conducted final leakage, pressure, and performance tests to meet stringent industry standards.

Through meticulous production control and strategic engineering, I contributed to the successful delivery of high-precision containment and biosafety solutions, ensuring seamless manufacturing, regulatory compliance, and customer satisfaction.