NFPS EPCO Project, notable for its achievement of coating the largest pipe ever with an injection mold in Shawcor’s global plant history.

🔹 Background & Engineering Challenges

The NFPS EPCO Project presented a unique engineering challenge, requiring modifications and enhancements in multiple areas to handle an unprecedented pipe size. Key objectives included:

✔ Structural and mechanical adjustments to existing systems for large-diameter pipe handling.

✔ Capacity assessment and process optimization to ensure safe and efficient execution.

✔ Development of new handling procedures to minimize risk and improve efficiency.

✔ Compliance with safety and engineering standards while executing the modifications.

🔹 Engineering Modifications & Process Development

1️⃣ Equipment & Infrastructure Adaptation

🔧 Structural Reinforcements – Evaluated and reinforced existing machinery to withstand increased load capacity.

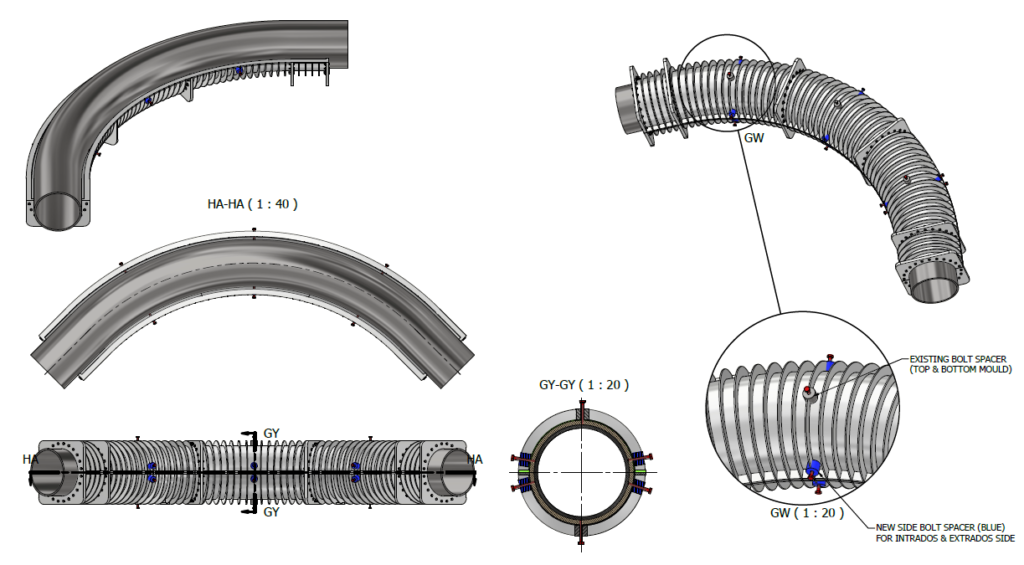

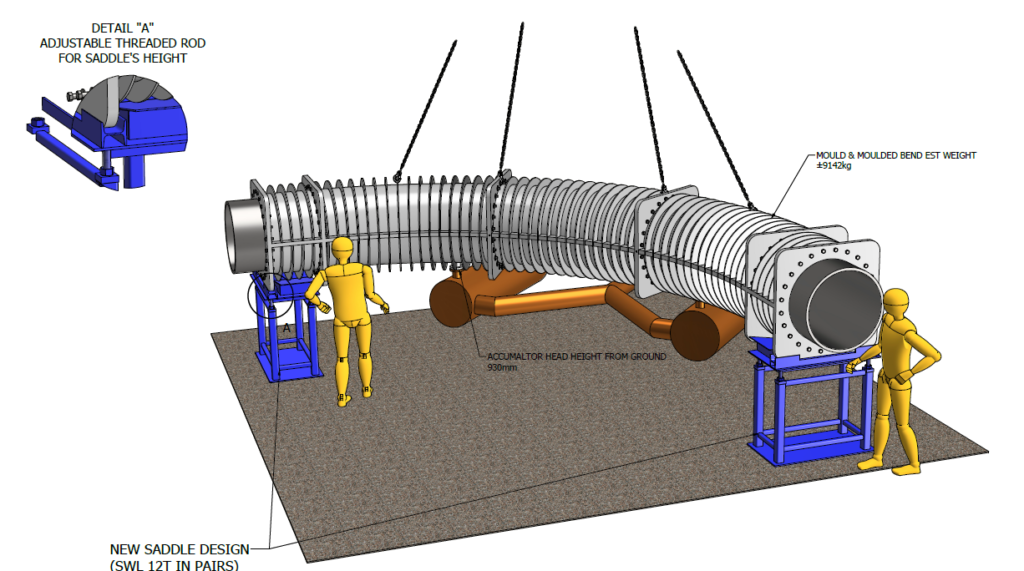

📐 Handling System Upgrades – Designed and implemented modifications to conveyor systems, rollers, and support structures.

🏗 Lifting & Transport Adjustments – Upgraded lifting and rotation mechanisms to ensure smooth handling of the large-diameter pipe.

2️⃣ Process Optimization & Workflow Management

📊 Workflow Redesign – Developed an optimized process sequence to integrate the new pipe dimensions.

⚙ Cycle Time Adjustment – Conducted time-motion studies to adjust production schedules accordingly.

🔍 Risk Mitigation Strategies – Identified potential failure points and implemented preventive engineering solutions.

3️⃣ Structural Analysis & Mechanical Validation

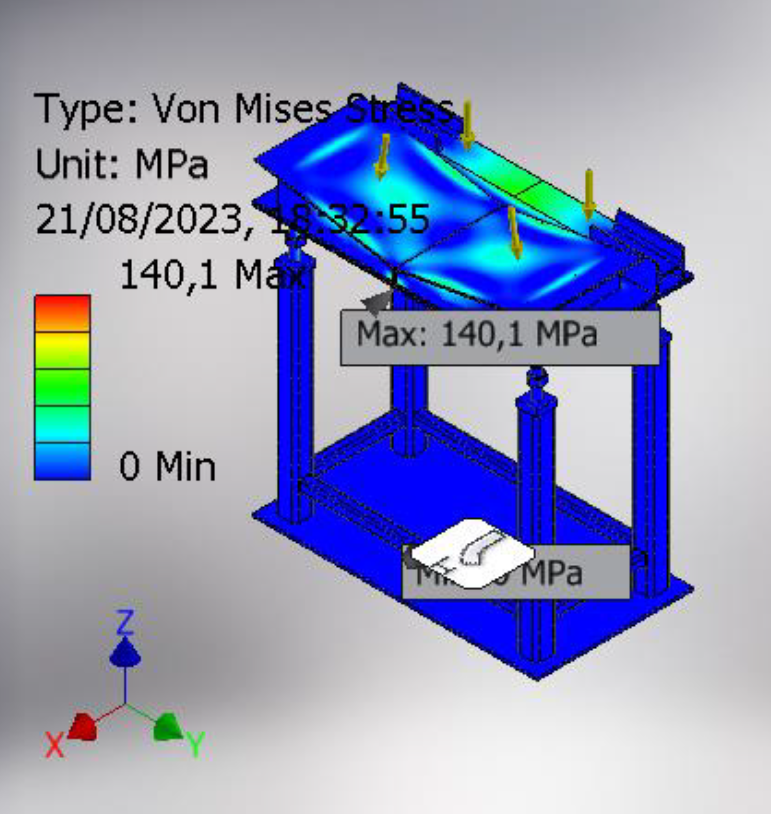

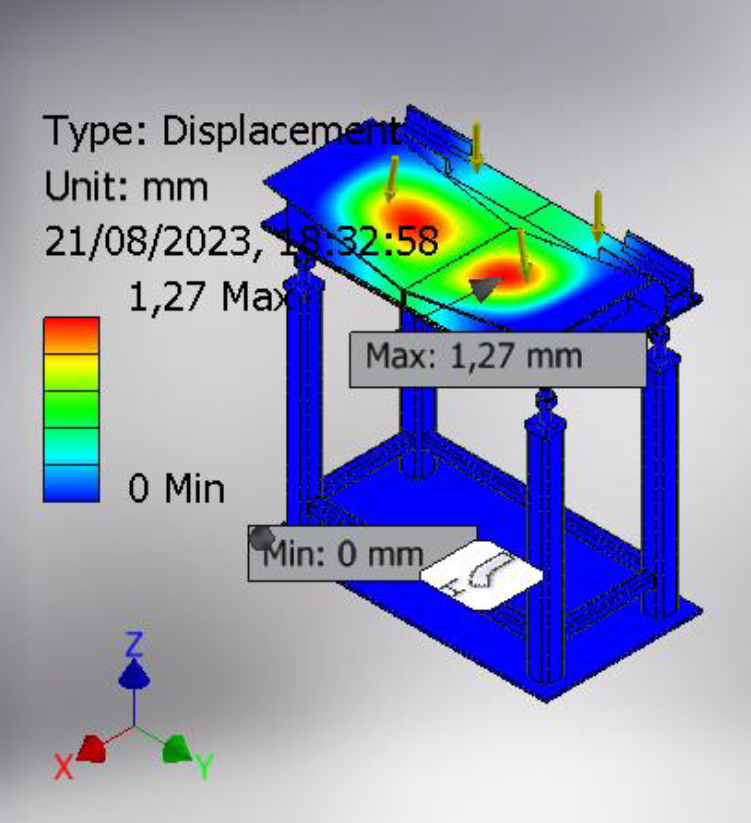

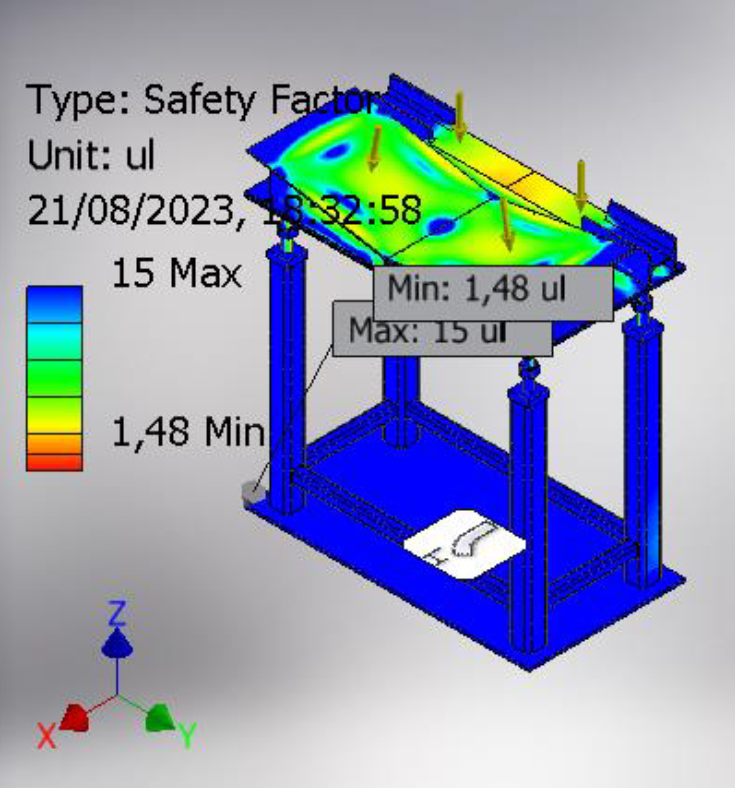

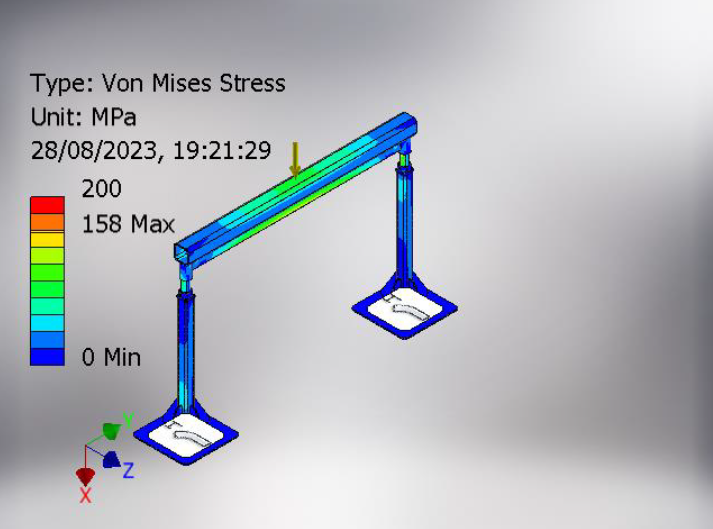

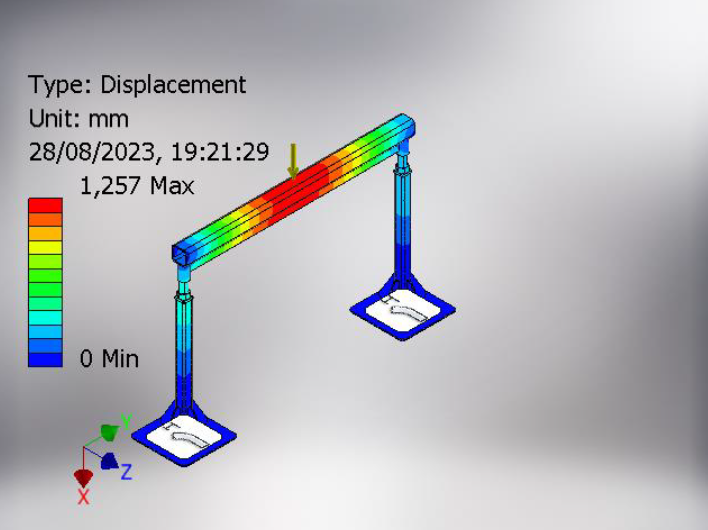

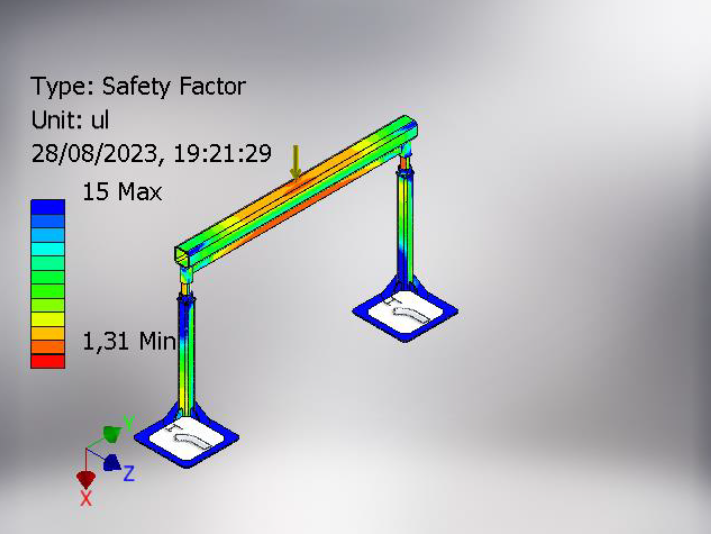

🛠 Finite Element Analysis (FEA) – Assessed stress distribution and load impact on handling equipment.

🔬 Mechanical Integrity Testing – Verified the stability and performance of modified support structures.

📏 Precision Calibration – Ensured dimensional accuracy and alignment in all modifications.

🔹 Operational Impact & Project Execution

🚀 Enhanced Handling Capacity – Enabled processing of larger and heavier pipes without compromising efficiency.

🏭 Improved Safety Measures – Implemented engineered controls to prevent structural overloading and minimize risks.

💡 Future Scalability – Established a framework for handling larger pipes in future projects.

🔹 Conclusion

The NFPS EPCO Project marked a groundbreaking advancement in Shawcor’s engineering capabilities. Through strategic modifications, process optimizations, and infrastructure reinforcements, the project successfully accommodated the largest pipe ever handled, reinforcing Shawcor’s position as a leader in advanced pipeline engineering solutions.