📌 Situation: The Washing Station Plant required modifications to comply with updated environmental regulations due to high water consumption and pollutant discharge.

🎯 Task: Lead the project to optimize water usage, upgrade treatment systems, and ensure full regulatory compliance with minimal operational disruption.

⚙ Action:

✔ Conducted water usage analysis and optimized treatment strategies.

✔ Upgraded equipment & automated processes to reduce waste.

✔ Secured regulatory approvals and ensured compliance.

✔ Managed budget efficiently, balancing cost-effectiveness and impact.

🏆 Result: Achieved full compliance, reduced water consumption, improved discharge quality, enhanced efficiency, and reinforced corporate sustainability. 🚀

Click to see Project details

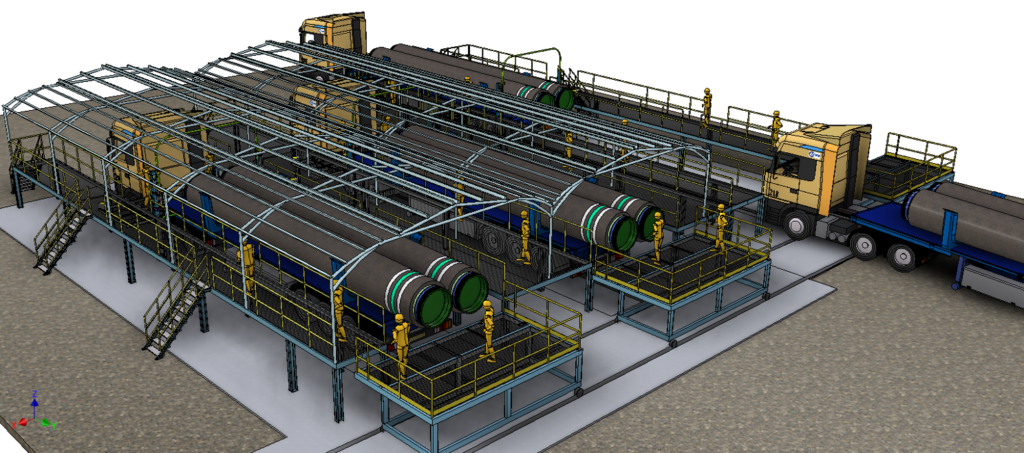

🎯 Objective: Upgrade the Washing Station Plant to align with updated environmental policies and regulations, ensuring sustainable and compliant operations.

🔹 Background & Objectives

With evolving environmental regulations, our Washing Station Plant required critical modifications to enhance compliance, sustainability, and operational efficiency. This CAPEX project was initiated to:

✅ Ensure Compliance – Meet or exceed updated environmental regulations and policies.

✅ Optimize Water Usage – Improve efficiency in water consumption and treatment.

✅ Reduce Environmental Impact – Minimize pollutants in discharged water.

✅ Enhance Operational Efficiency – Streamline washing processes and reduce waste.

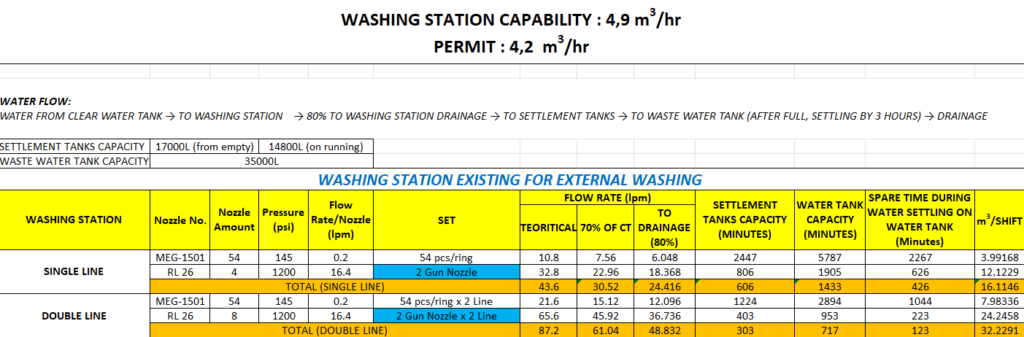

A comprehensive water usage calculation was conducted to assess current consumption patterns and develop optimized treatment strategies.

🔹 Project Scope & Implementation

1️⃣ Water Treatment System Enhancement

🔍 Baseline Water Usage Study – Assessed current water consumption and pollutant levels.

🔬 Chemical & Biological Treatment – Integrated chemical dosing and biological treatment methods to achieve clean water discharge standards.

📊 Regulatory Compliance Analysis – Ensured water quality met legal discharge limits.

2️⃣ Process Optimization & Efficiency Improvements

⚙ Equipment Upgrades – Installed low-consumption, high-efficiency washing systems to reduce water waste.

♻ Water Recycling & Reuse – Introduced closed-loop recycling to minimize freshwater consumption.

🔄 Process Semi-Automation – Implemented smart control systems to optimize water flow and reduce manual intervention.

3️⃣ Compliance & Environmental Standards Implementation

📜 Adherence to Regulations – Ensured compliance with local and international environmental laws.

✅ Certification & Approval – Conducted validation testing to receive environmental compliance certification.

🔹 Key Benefits

✅ Regulatory Compliance – Ensures full adherence to updated environmental laws.

✅ Water Conservation – Optimized water use, reducing consumption.

✅ Pollutant Reduction – Enhanced treatment reduces contaminants, improving discharge quality.

✅ Cost Savings – Reduced water usage lowers operational costs.

✅ Sustainable Operations – Supports corporate social responsibility and environmental goals.

🔹 Budget Management & Execution Strategy

💰 Optimized Investment – Focused on cost-effective, high-impact modifications.

🛠 Minimal Disruption – Implemented upgrades in phased execution to avoid production downtime.

🔹 Conclusion

The Washing Station Plant Modification Project is a strategic investment in environmental sustainability, ensuring regulatory compliance, improved water efficiency, and reduced environmental impact. By implementing advanced water treatment systems, optimizing washing processes, and adopting real-time monitoring, this project strengthens the company’s commitment to sustainable operations and corporate responsibility.

🚀 This initiative not only meets current regulatory standards but also enhances overall operational efficiency. 🌱💧