📅 Project Timeline: Q3 2023 – Ongoing

💰 Current Project Value: USD 101,000

💰 Estimated Future Value: USD 3 Million

🎯 Objective: Upgrade and optimize emission control systems to comply with new environmental regulations and significantly reduce harmful emissions.

Situation:

Stricter environmental regulations necessitated an upgrade to our emission control systems. The existing setup posed regulatory risks and environmental concerns, requiring advanced solutions to meet compliance standards while maintaining operational efficiency.

Task:

✅ Implement Diesel Oxidation Catalyst (DOC) Systems to minimize harmful emissions.

✅ Upgrade and integrate emission control technologies, including catalytic converters and scrubbers.

✅ Optimize system performance to achieve compliance and operational efficiency.

✅ Manage costs effectively while maximizing environmental benefits.

Action:

🔍 Emission Analysis & Compliance Assessment – Evaluated CO, NOx, and particulate emissions against new standards.

🔧 Technology Implementation – Installed DOC Systems capable of:

- 96% CO Reduction

- 16% NOx Reduction

- 25-30% Particulate Emission Reduction (Soluble Organic Fraction – SOF)

🛠 System Integration & Optimization – Ensured seamless compatibility with existing infrastructure.

📊 Performance Monitoring & Testing – Conducted real-time tracking to verify emission reductions.

💰 Cost Management Strategy – Balanced investments to optimize current and future environmental benefits.

Result:

✅ Regulatory Compliance – Fully aligned with updated environmental standards.

✅ Drastic CO Reduction – Successfully reduced carbon monoxide emissions by 96%.

✅ NOx Reduction – Achieved a 16% decrease in nitrogen oxide emissions.

✅ Dust/Particulate Emissions – Increased by 84%, but still within permissible limits.

✅ Improved Air Quality – Decreased hydrocarbon and particulate emissions, contributing to cleaner operations.

✅ Long-Term Sustainability – Positioned for future expansion with an estimated project value of USD 3 million.

✅ Operational Efficiency – Achieved cleaner and more sustainable energy use without sacrificing performance.

Conclusion:

The Air Emission Standardization Project is a key initiative in our sustainability strategy, significantly reducing emissions while ensuring compliance with stringent regulations. This investment strengthens our commitment to environmental responsibility and operational excellence, paving the way for a cleaner, more efficient future. 🌿🔥

Click to see Project details

📅 Project Timeline: Q3 2023 – Ongoing

💰 Current Project Value: USD 101,000

💰 Estimated Future Value: USD 3 Million

🎯 Objective: Upgrade and optimize emission control systems to comply with new environmental regulations, significantly reducing harmful emissions while enhancing operational efficiency.

🔹 Background & Objectives:

With increasing environmental regulations, our existing air emission control systems required critical upgrades to ensure compliance with stringent air quality standards. This CAPEX project was initiated to:

- Reduce harmful carbon monoxide (CO), nitrogen oxides (NOx), and particulate emissions

- Enhance the efficiency of emission treatment processes

- Ensure compliance with evolving environmental laws and regulatory standards

- Minimize our environmental footprint while maintaining operational efficiency

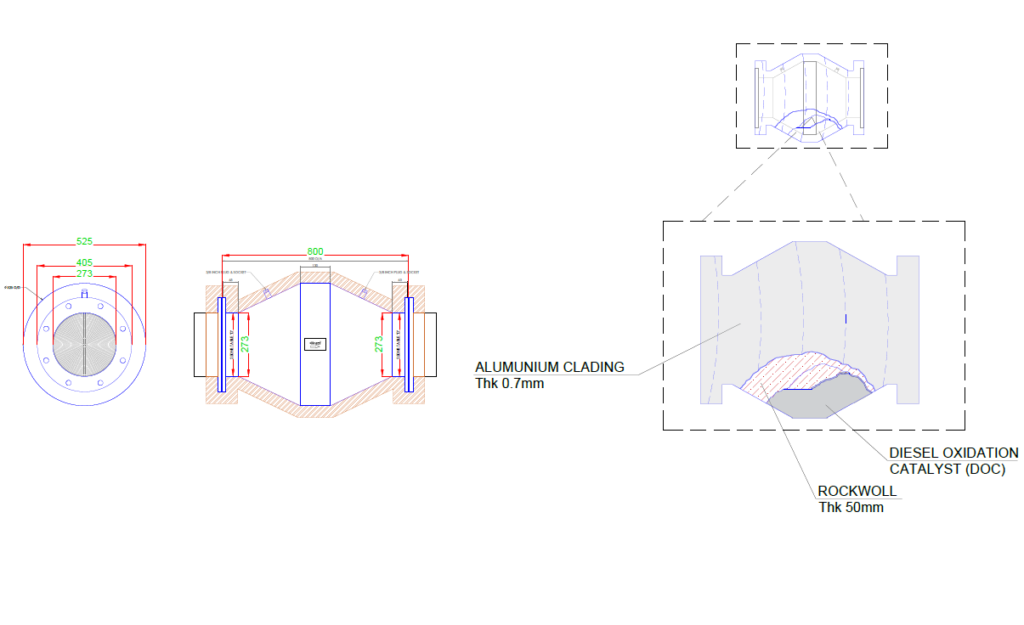

A Diesel Oxidation Catalyst (DOC) System was chosen as the key solution, offering high conversion efficiency for pollutants with minimal energy losses and maintenance costs.

🔹 Project Scope & Implementation:

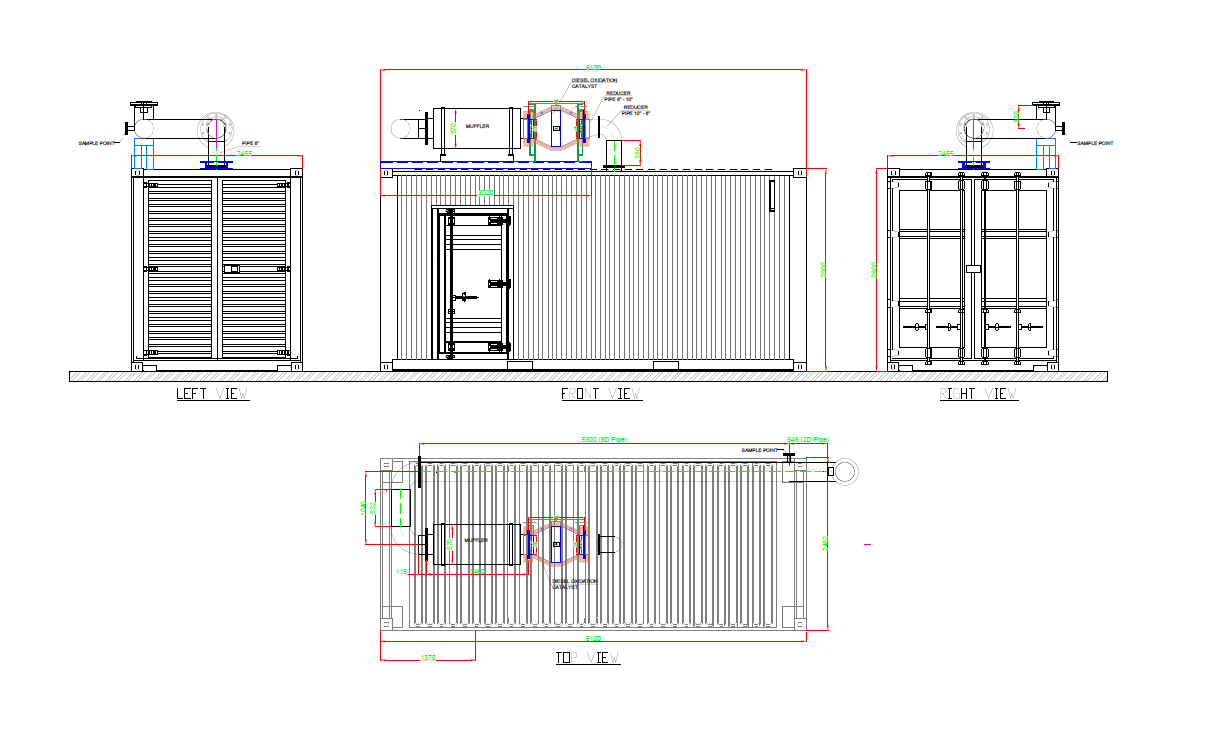

The project included engineering, procurement, installation, and validation of DOC systems across emission sources, ensuring compatibility and optimal performance.

1️⃣ Emission Assessment & System Analysis:

🔍 Baseline Study – Measured pre-upgrade emission levels and system inefficiencies.

🔬 Pollutant Identification – Identified primary emission sources of CO, SO2, HC, and particulates.

📊 Compliance Gap Analysis – Evaluated where improvements were needed to meet environmental regulations.

2️⃣ Diesel Oxidation Catalyst (DOC) Installation:

🔧 Advanced Emission Control Technology – Implemented a DOC system capable of:

- 96% CO Reduction – Near elimination of toxic carbon monoxide emissions.

- 16% NOx Reduction – Lower nitrogen oxide levels for improved air quality.

- 25-30% Particulate Emission Reduction (Soluble Organic Fraction – SOF).

- 84% Increase in Dust/Particle Emissions, but still within regulatory standards.

🛠 Infrastructure Upgrades – Modified existing systems to support DOC integration.

🔄 System Compatibility & Calibration – Ensured seamless functionality with existing combustion and exhaust infrastructure.

3️⃣ Performance Monitoring & Testing:

📊 Validation Testing – Conducted leak detection, pressure testing, and performance assessments.

✅ Regulatory Certification – Verified compliance with environmental standards.

🔹 Technical Highlights & Emission Reduction Mechanism:

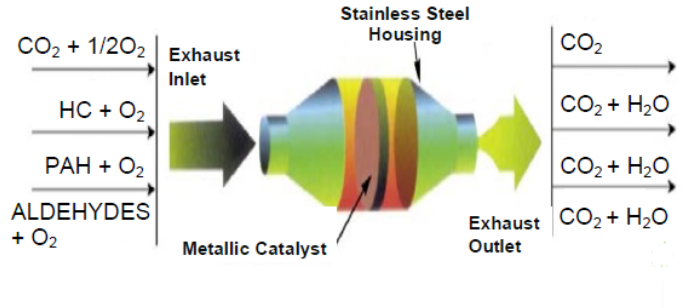

The DOC system employs an oxidation catalyst to convert hazardous pollutants into less harmful compounds, using advanced catalytic reactions:

🔵 CO Oxidation: CO + O₂ → CO₂ (96% CO Reduction)

🟢 HC Oxidation: HC + O₂ → CO₂ + H₂O (85% Hydrocarbon Reduction)

🟡 NOx Reduction: Selective catalytic reactions reduce nitrogen oxide pollutants (16% Reduction).

The technology is highly adaptable and can be scaled up to accommodate future regulatory changes.

🔹 Environmental & Operational Benefits:

The project delivered significant environmental and operational advantages:

✅ Regulatory Compliance – Fully meets government & industry emission standards.

✅ Significant CO Reduction – Removed toxic CO emissions, ensuring cleaner air.

✅ Optimized NOx & Particulate Control – Maintained air quality within safe levels.

✅ Energy-Efficient Performance – No significant impact on system power consumption.

✅ Minimal Maintenance Costs – DOC systems require less upkeep than traditional scrubbers or filters.

✅ Scalability for Future Expansion – The system is designed to accommodate future upgrades, supporting a $3M expansion plan.

🔹 Budget Management & Execution Strategy:

The project was executed within the USD 101,000 budget through:

💰 Strategic Procurement – Sourced cost-effective catalytic materials without compromising quality.

🛠 Efficient Installation Process – Minimized system downtime by integrating work schedules with plant operations.

📊 Rigorous Quality Control – Ensured all components met performance & safety benchmarks before commissioning.

Through effective cost management, the project maximized emission reduction benefits while maintaining financial discipline.

🔹 Future Expansion & Scalability:

The project is part of a long-term investment plan, estimated to grow into a USD 3 million initiative for:

📈 Scaling Up Emission Controls – Expanding DOC coverage to additional critical emission points.

🔬 Advanced Monitoring Systems – Implementing AI-based pollution tracking for real-time performance adjustments.

🏭 Further Infrastructure Enhancements – Upgrading exhaust stacks and ventilation systems for improved dispersion.

With future expansions, the company aims to fully eliminate hazardous emissions, ensuring environmental sustainability & regulatory leadership.

🔹 Conclusion:

The Air Emission Standardization CAPEX Project is a strategic step toward a cleaner, safer, and more sustainable future. By integrating DOC technology, we achieved 96% CO reduction, 16% NOx reduction, and significant compliance improvements without disrupting operations.

This initiative reinforces our commitment to environmental responsibility while positioning us for future regulatory changes and technological advancements. 🌍♻️