📅 Project Timeline: Q3 2023

💰 Project Budget: USD 40,000

🎯 Objective: Replace a corroded natural gas pipeline to enhance safety and operational reliability

Situation:

The existing natural gas pipeline had suffered from severe corrosion, posing a significant safety risk and potential operational failures. A replacement was essential to maintain system integrity, prevent leaks, and ensure compliance with industry safety regulations.

Task:

The project was designed to:

✅ Remove the corroded pipeline and install a new corrosion-resistant system.

✅ Enhance safety by preventing potential gas leaks and system failures.

✅ Ensure compliance with industry regulations and safety standards.

✅ Integrate the new pipeline with minimal disruption to plant operations.

✅ Complete the project within the USD 40,000 budget.

Action:

🔍 Pipeline Inspection & Risk Assessment – Conducted a thorough evaluation to assess corrosion impact

🏗 Pipeline Replacement – Installed a new, corrosion-resistant natural gas pipeline

⚙️ System Integration – Seamlessly connected the new pipeline into the existing gas distribution network

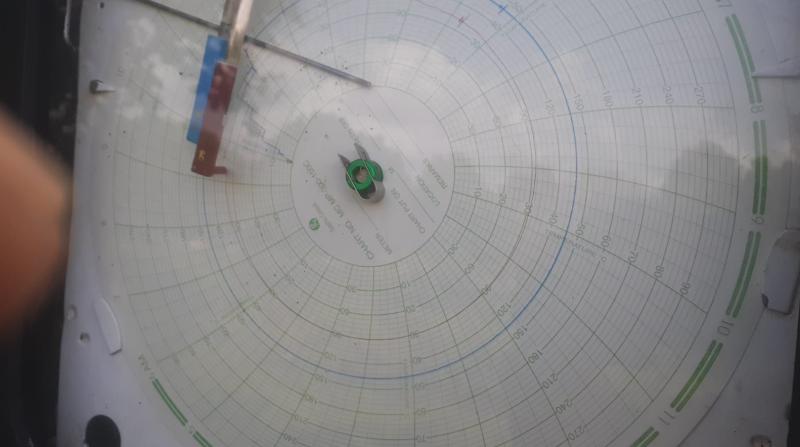

📊 Testing & Safety Validation – Performed leak tests, pressure tests, and safety verifications before commissioning

💰 Budget Management – Optimized procurement and resource allocation to stay within financial limits

Result:

🔥 Enhanced Fire & Gas Safety – Eliminated risks of leaks, explosions, and failures.

✅ Regulatory Compliance Achieved – Fully aligned with industry and safety regulations.

⚡ Improved Operational Reliability – Ensured uninterrupted gas supply and system performance.

📉 Minimal Downtime – Completed the transition without significant operational disruptions.

💲 On-Time & Within Budget – Delivered successfully while optimizing resources.

This CAPEX project was critical in safeguarding infrastructure, ensuring regulatory compliance, and enhancing long-term operational safety. 🔧🔥

New NG Pipeline Installation

Click to see Project details

📅 Project Timeline: Q3 2023

💰 Project Budget: USD 40,000

🎯 Objective: Replace a corroded natural gas pipeline to enhance safety and operational reliability

Objective:

This project focused on the replacement of a corroded natural gas pipeline to mitigate safety risks and ensure uninterrupted gas distribution. The existing pipeline had deteriorated due to corrosion, posing a risk of leaks, operational failures, and regulatory non-compliance.

By installing a new, corrosion-resistant pipeline, the project enhanced system reliability, operational safety, and compliance with industry standards while minimizing downtime and disruptions.

Replacement & Safety Enhancements:

The project included key engineering upgrades:

🔍 Pipeline Assessment & Risk Analysis – Identified corrosion-affected sections and evaluated risk levels.

🔧 Pipeline Removal & Replacement – Installed a new, corrosion-resistant pipeline to prevent leaks and ensure long-term safety.

🛠 Infrastructure Integration – Connected the new pipeline to the existing gas distribution system with minimal operational disruption.

📊 Inspection & Compliance Testing – Conducted pressure tests, leak detection, and regulatory inspections to ensure compliance with safety standards.

💰 Cost-Effective Execution – Optimized budget allocation to complete the project within the USD 40,000 budget.

Unlike a full infrastructure overhaul, this targeted replacement approach ensured maximum safety improvements with minimal cost and downtime.

Compliance & Risk Mitigation:

The upgraded pipeline meets stringent safety regulations and ensures long-term reliability:

✅ Regulatory Compliance – Adheres to industry codes for natural gas pipeline safety.

✅ Leak Prevention – Eliminates corrosion risks and improves pipeline integrity.

✅ System Reliability – Enhances gas distribution efficiency and reduces operational hazards.

✅ Sustainable Infrastructure – Ensures long-term performance with minimal maintenance requirements.

Operational Impact:

The pipeline replacement project resulted in significant operational improvements:

🚀 Enhanced Safety – Reduced leak potential risks and improved fire safety measures.

🔄 Improved System Efficiency – Ensured uninterrupted gas supply with optimized distribution.

📉 Reduced Maintenance Costs – Lowered the need for frequent repairs and emergency interventions.

📈 Increased Reliability – Strengthened infrastructure durability and minimized downtime risks.

Budget Management & Execution Strategy:

The project was successfully executed within the USD 40,000 budget through efficient resource allocation:

💰 Optimized Material Procurement – Used cost-effective yet high-quality materials for long-term performance.

🛠 Efficient Engineering Execution – Minimized disruptions by coordinating installation with operational schedules.

📊 Rigorous Testing & Quality Control – Ensured the pipeline met all safety and performance standards before commissioning.

With no budget overruns, the project delivered maximum safety and reliability while maintaining financial discipline.

Conclusion:

The Natural Gas Pipeline Replacement project successfully enhanced safety, operational efficiency, and regulatory compliance. By eliminating corrosion risks and upgrading critical infrastructure, the project ensured long-term reliability and minimized potential hazards.

This CAPEX initiative reflects our commitment to continuous improvement, safety, and sustainable operations, ensuring our infrastructure remains resilient and future-ready. 🔧🔥