📅 Project Timeline: Q1 2023 – Q2 2023

💰 Project Budget: USD 202,000

🎯 Objective: Upgrade outdated equipment to meet client specifications and enhance production reliability

Situation:

The Asphalt Enamel Plant relied on outdated equipment that introduced inconsistencies in production and posed a risk to meeting client quality requirements. To maintain high product standards and improve operational reliability, an upgrade was essential. The CAPEX project aimed to modernize key equipment and integrate advanced process control systems.

Task:

The project was designed to:

✅ Replace obsolete machinery with advanced equipment to eliminate error sources

✅ Enhance automation and process control for consistent product quality

✅ Ensure compliance with stringent client specifications and industry standards

✅ Minimize downtime during the transition to the upgraded system

✅ Complete within the allocated budget of USD 202,000

Action:

🔍 System Evaluation & Gap Analysis – Identified inefficiencies and determined the best upgrade strategy

🏗 Equipment Procurement & Installation – Installed modern machinery with enhanced accuracy and reliability

🤖 Automation & Monitoring System Integration – Implemented real-time monitoring for improved process control

📊 Testing & Validation – Conducted trials to verify performance and ensure seamless production continuity

💰 Budget Optimization – Managed resources effectively to complete the project within financial constraints

Result:

🚀 Enhanced Production Reliability – Reduced errors and improved process consistency

✅ Client Requirements Met – Production aligned with strict quality specifications

⚡ Increased Efficiency – Improved throughput and operational uptime

📉 Minimal Downtime – Transition executed without major disruptions

💲 On-Time & Within Budget – Successfully delivered with optimized resource utilization

This CAPEX project reinforced production excellence, client satisfaction, and long-term operational efficiency, ensuring that the Asphalt Enamel Plant remains competitive and compliant with industry demands. 🔧🎯

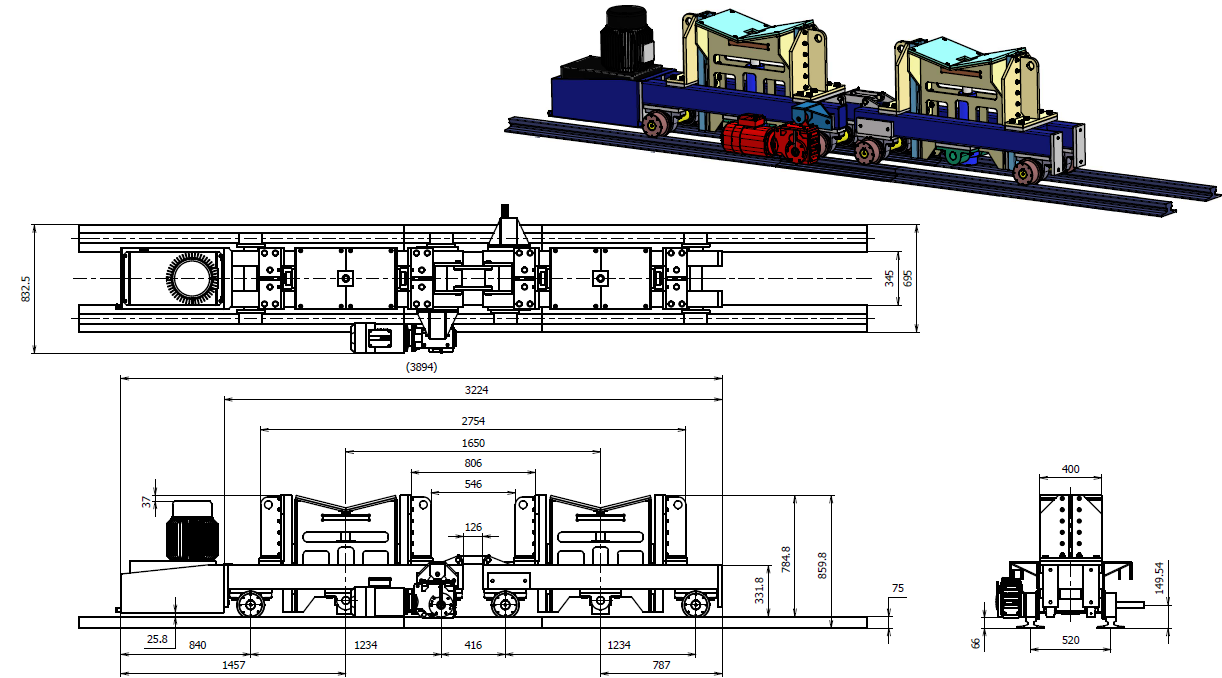

Design (by AY) the equipment (Transfer Buggy) by using Autodesk Inventor.

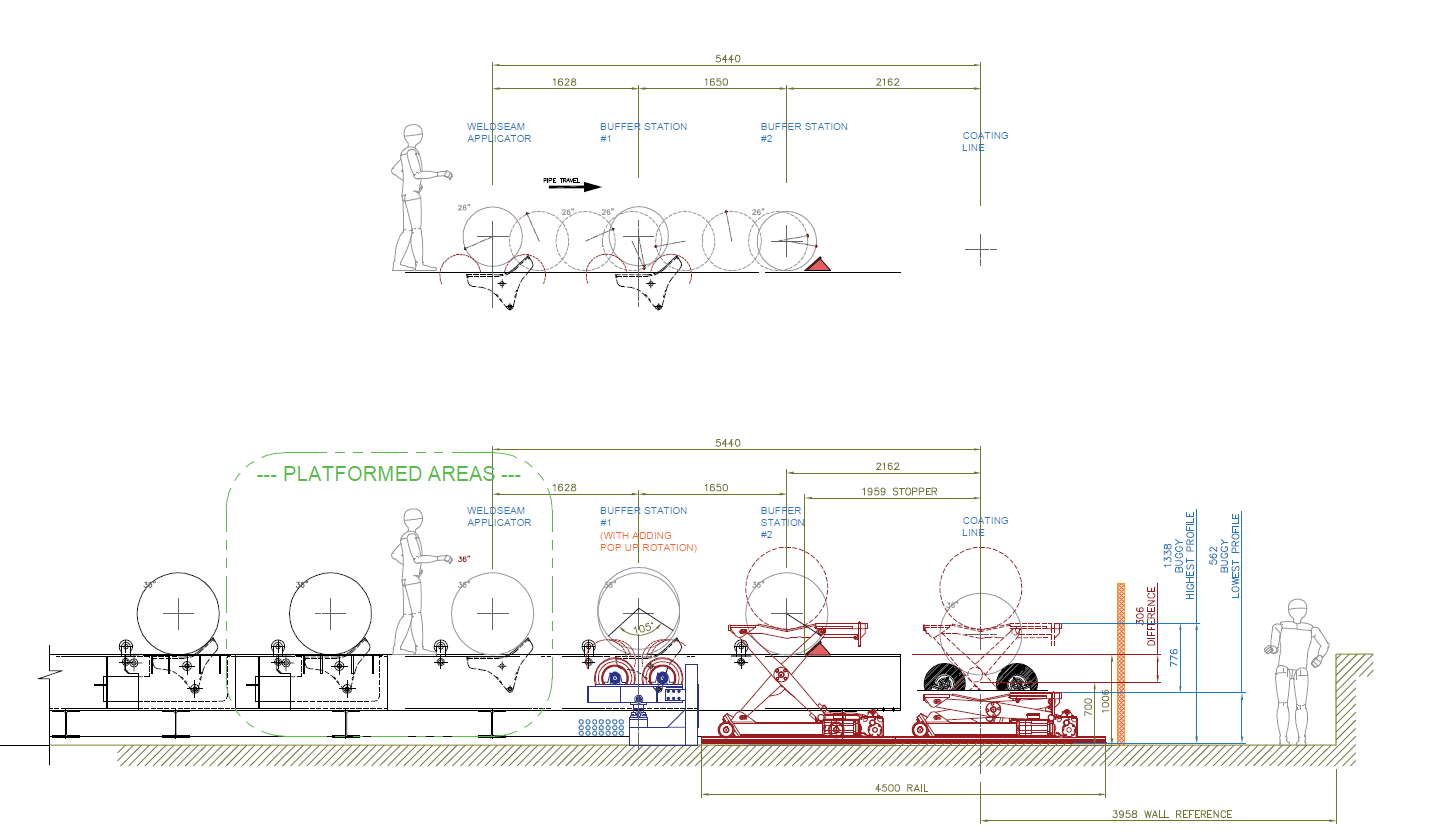

Finalizing detailed design drawings for the CAPEX project upgrade by using Autodek AutoCAD. These blueprints are the foundation for accurate execution and successful project delivery, ensuring every component is aligned with safety standards and operational goals. Design precision is key to achieving our project’s objectives.

Click to see Project details

📅 Project Timeline: Q1 2023 – Q2 2023

💰 Project Budget: USD 202,000

🎯 Objective: Upgrade outdated equipment to improve production reliability and meet client quality requirements

Objective:

This project focused on modernizing outdated equipment in the Asphalt Enamel Plant to enhance process reliability, product consistency, and operational efficiency. The previous system introduced potential error sources, affecting quality control and production stability.

By replacing obsolete machinery with advanced technology, the project ensured compliance with client specifications, minimized process variability, and optimized manufacturing performance.

Upgrade Details:

The project included several key engineering improvements:

🔍 System Evaluation & Gap Analysis – Assessed inefficiencies in the existing process and identified required upgrades.

🏗 Equipment Procurement & Installation – Replaced outdated machinery with modern, high-precision equipment for enhanced process control.

🤖 Automation & Process Monitoring – Integrated real-time monitoring systems to improve consistency and minimize defects.

⚙️ Testing & Validation – Conducted rigorous performance trials to ensure seamless integration and compliance with quality standards.

💰 Budget & Resource Optimization – Allocated resources efficiently to achieve maximum impact within budget.

Unlike a full system overhaul, this upgrade targeted critical inefficiencies to maximize performance improvements while controlling costs.

Compliance & Quality Assurance:

The modernized production system aligns with client and industry standards, delivering the following benefits:

✅ Strict Compliance – Meets client requirements and industry regulations.

✅ Process Stability – Reduces variability, ensuring uniform product quality.

✅ Operational Efficiency – Optimized workflow and reduced process interruptions.

✅ Sustainable Performance – Future-ready system for long-term reliability and scalability.

Operational Impact:

The upgraded Asphalt Enamel Plant delivered tangible improvements in efficiency and reliability:

🚀 Improved Production Reliability – Minimized downtime and operational disruptions.

⚡ Enhanced Product Quality – Eliminated error sources for consistent, high-quality output.

📉 Reduced Process Variability – Ensured compliance with stringent client specifications.

📈 Optimized Throughput – Increased plant efficiency without compromising safety or compliance.

Budget Management & Execution Strategy:

The project was successfully completed within the USD 202,000 budget through strategic resource allocation:

💰 Cost-Effective Procurement – Sourced high-quality components while maintaining cost efficiency.

🛠 Optimized Engineering Execution – Implemented upgrades without major disruptions to production.

📊 Testing & Performance Analysis – Ensured regulatory alignment and verified process improvements.

With no budget overruns, the project achieved maximum efficiency and reliability while maintaining financial discipline.

Conclusion:

The Asphalt Enamel Plant Upgrade successfully modernized production capabilities, ensuring client satisfaction, process reliability, and long-term operational efficiency. By focusing on key technological advancements, the project eliminated error sources, improved automation, and strengthened production consistency.

This CAPEX initiative reinforces our commitment to quality, compliance, and continuous improvement, ensuring that our plant remains competitive and future-ready. 🔧🚀