Project Timeline: Q2 2023 – Q1 2024

Project Budget: USD 206,000

Objective: Upgrade plant capabilities to meet coating requirements for Buckle Arrestor pipes in the Scarborough project

Situation:

The existing equipment at the coating plant required enhancements to meet the precise requirements for coating Buckle Arrestor pipes, a critical component of the Scarborough project. Without these upgrades, the plant risked inefficiencies, quality issues, and non-compliance with project specifications.

Task:

The project aimed to:

✅ Upgrade pipe handling systems for improved efficiency and precision

✅ Enhance the extraction system in the painting spray area to improve air quality

✅ Ensure compliance with Scarborough project quality standards

✅ Complete within the USD 206,000 budget while maintaining operational efficiency

Action:

🔍 System Assessment – Evaluated existing equipment and identified performance gaps

🚧 Pipe Handling Upgrade – Modernized handling systems for better precision and throughput

💨 Extraction System Enhancement – Improved ventilation to ensure a safer work environment

📑 Regulatory & Quality Compliance – Aligned upgrades with Scarborough project standards

💰 Budget & Timeline Management – Controlled costs while ensuring timely execution

Result:

🏗 Enhanced Processing Efficiency – Improved handling of large-diameter pipes

🌍 Safer Work Environment – Better ventilation and air quality in spray areas

✅ Compliance Achieved – Met all Scarborough project technical and quality standards

⚙️ Optimized Operations – Reduced downtime and improved workflow

The project successfully aligned the plant’s capabilities with project requirements, ensuring high-quality coated pipes while maintaining efficiency and compliance. 🚀

Click to see Project details

📅 Project Timeline: Q2 2023 – Q1 2024

💰 Project Budget: USD 206,000

🎯 Objective: Upgrade plant capabilities for Buckle Arrestor pipe coating in the Scarborough project

Objective:

This project aimed to enhance the plant’s capabilities to meet the precise requirements for coating Buckle Arrestor pipes, a key component of the Scarborough project. The existing equipment required upgrades to improve processing efficiency, ensure compliance with technical standards, and maintain high-quality coating performance.

By modernizing the pipe handling and extraction systems, the plant achieved better operational efficiency, reduced downtime, and enhanced safety while meeting the stringent requirements of the Scarborough project.

Upgrade Details:

The project involved targeted engineering improvements to optimize the coating process, including:

🔍 System Evaluation & Process Analysis – Assessed existing infrastructure to identify performance gaps and compliance requirements.

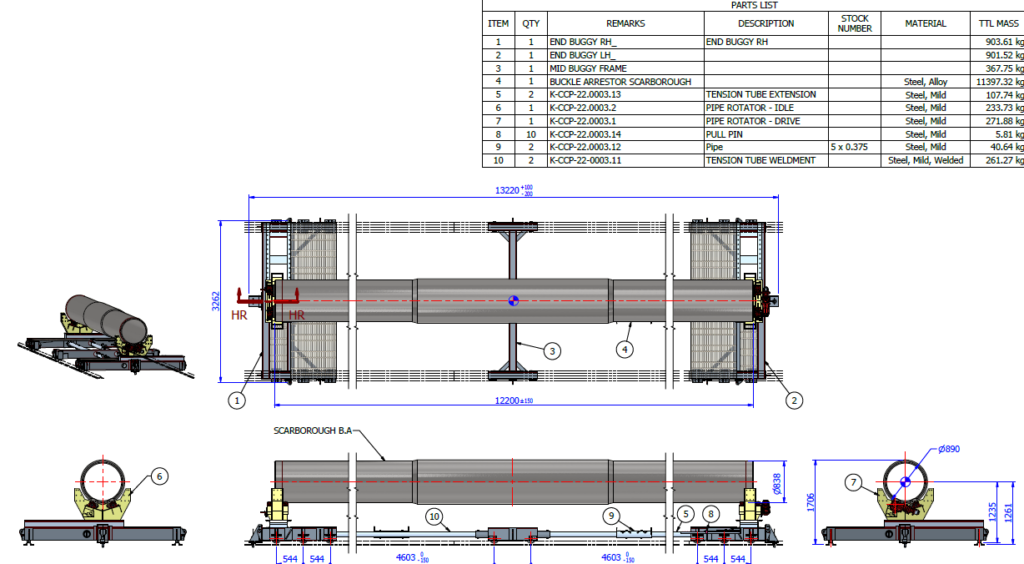

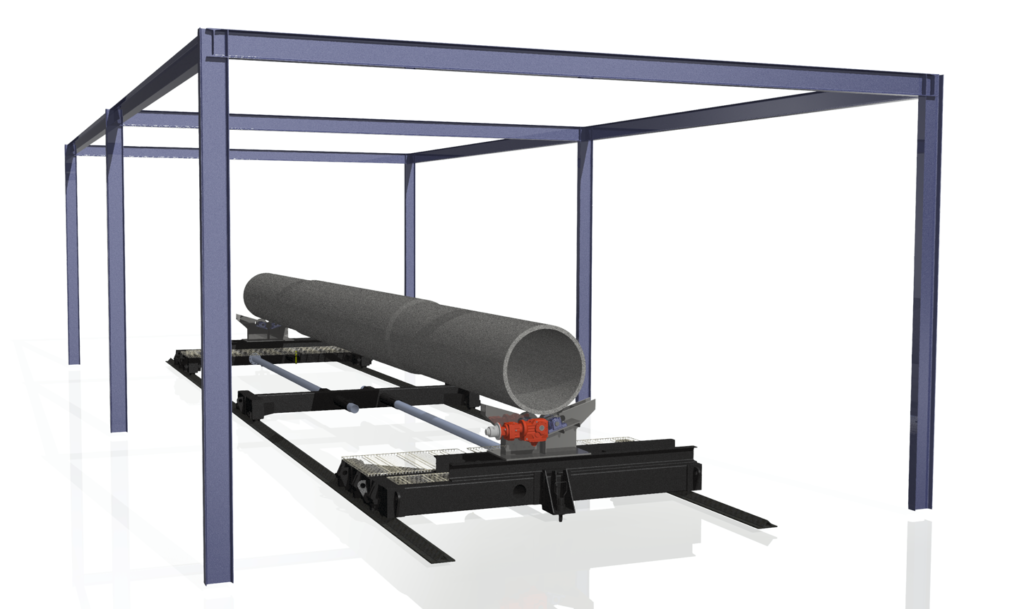

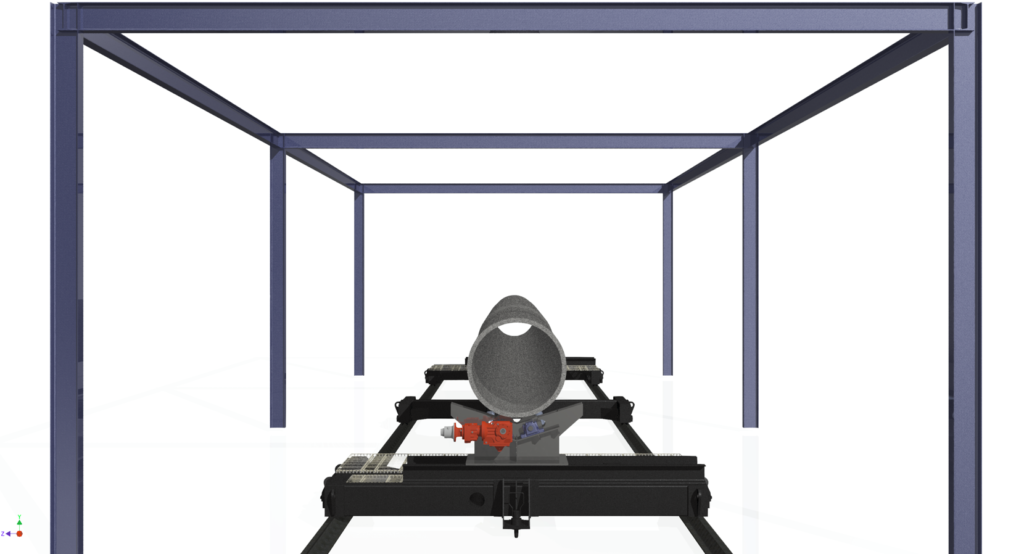

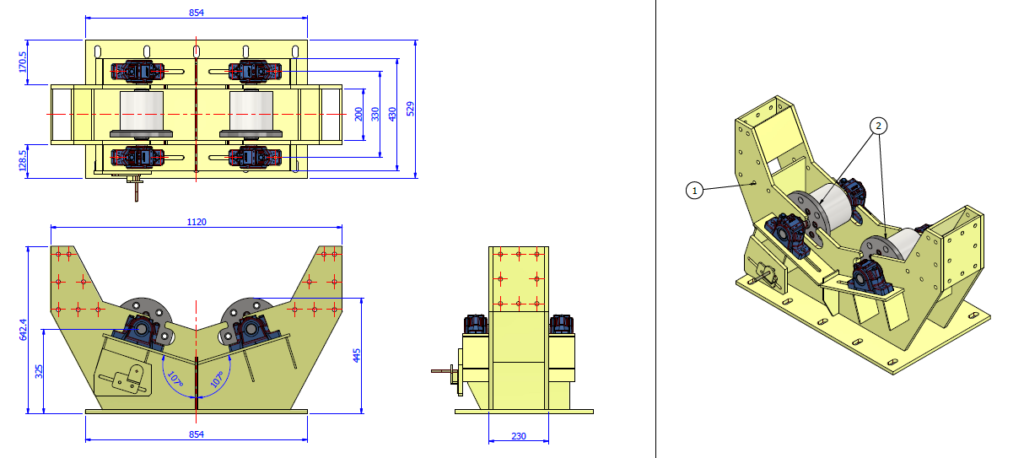

🏗 Pipe Handling System Upgrade – Modernized handling systems to improve efficiency and precision in large-diameter pipe processing.

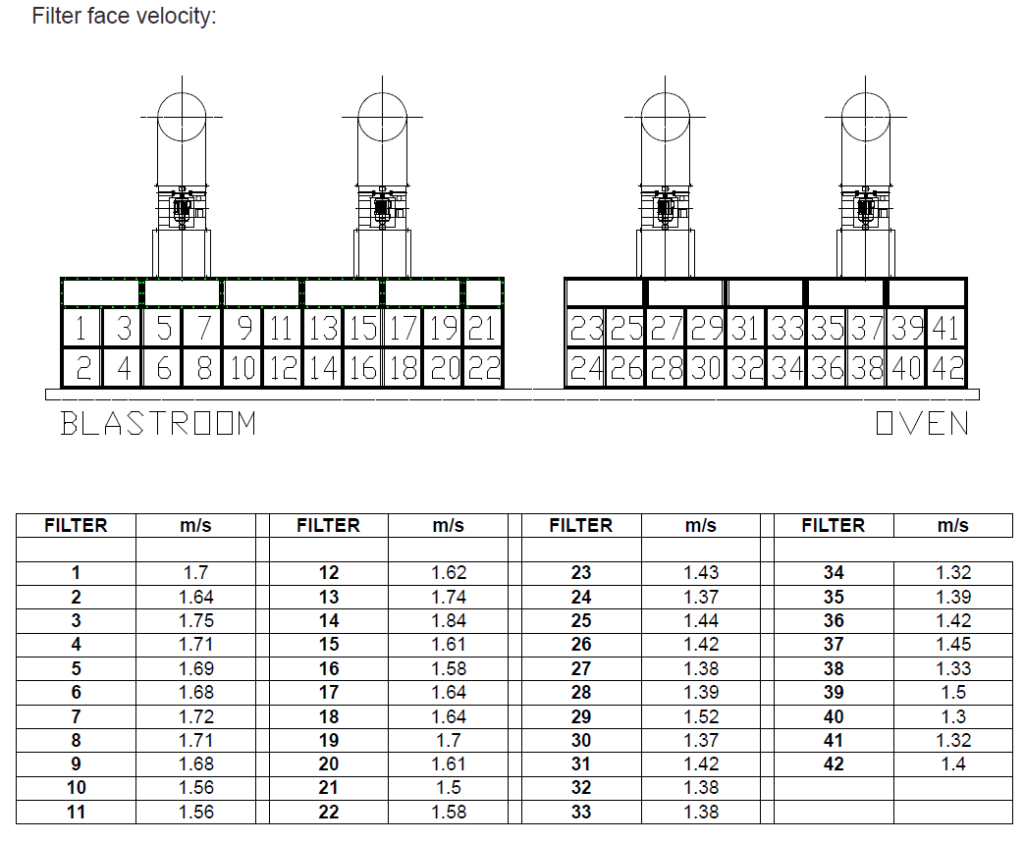

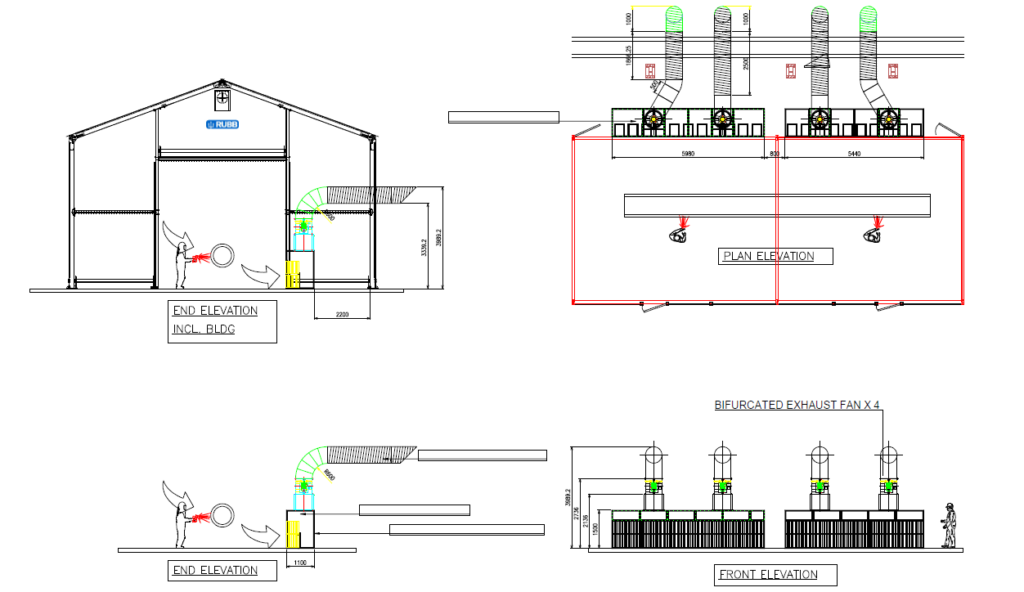

💨 Extraction System Enhancement – Upgraded ventilation in the painting spray area to improve air quality and ensure a safer working environment.

📑 Quality & Compliance Alignment – Ensured all upgrades met Scarborough project specifications and industry standards.

Instead of a full system overhaul, the project focused on strategic enhancements that maximized performance while staying within the allocated budget.

Compliance & Safety:

The upgraded equipment ensures alignment with technical and safety requirements, providing key benefits:

✅ Regulatory & Project Compliance – Meets all Scarborough project specifications and industry standards.

✅ Enhanced Ventilation – Improved air quality in the painting spray area, reducing worker exposure to hazardous fumes.

✅ Improved Safety – Reduced operational risks with more efficient handling and coating processes.

✅ Operational Reliability – Optimized equipment performance to minimize downtime and enhance production efficiency.

Operational Impact:

The equipment upgrades provide significant operational advantages:

🏗 Increased Efficiency – Improved handling and processing of large-diameter pipes.

🌍 Safer Work Environment – Better ventilation and reduced exposure to hazardous substances.

✅ Quality Assurance – Ensured uniform coating application to meet project specifications.

⚡ Optimized Production – Reduced bottlenecks, improved workflow, and enhanced output quality.

Budget Management & Execution Strategy:

The project was successfully completed within the USD 206,000 budget by adopting a cost-effective approach:

💰 Resource Optimization – Prioritized high-impact upgrades to maximize efficiency.

🛠 Strategic Procurement – Sourced durable, high-performance equipment to ensure long-term reliability.

📊 Testing & Validation – Conducted performance tests to confirm compliance with project requirements.

By efficiently managing resources, the project achieved its goals without exceeding budget constraints.

Conclusion:

The Buckle Arrestor Pipe Coating Plant Upgrade successfully improved operational efficiency, safety, and compliance with Scarborough project requirements. Through targeted enhancements in pipe handling and extraction systems, the project delivered a more efficient, reliable, and high-quality coating process.

This upgrade strengthens the plant’s long-term competitiveness, safety standards, and production capabilities, ensuring continued success in high-specification coating projects.

🔧 Project Successfully Implemented – Enhancing Efficiency & Compliance! 🚀