Project Timeline: Q2 2023 – Q4 2023

Project Budget: USD 70,000

Objective: Enhance airflow capacity to improve air quality and operational safety

Situation:

The Acid Wash Booth in the Fusion Bonded Epoxy (FBE) Plant had inadequate airflow, causing hazardous fume buildup, worker safety concerns, and regulatory non-compliance. An upgrade was needed to increase airflow capacity by min 100% and improve workplace conditions.

Task:

The project aimed to:

✅ Enhance airflow capacity by 100%

✅ Improve ventilation & worker safety

✅ Ensure regulatory compliance

✅ Complete within USD 70,000 budget

Action:

🔍 System Assessment – Identified airflow limitations

🏗 New Exhaust Chimney – Installed with high-performance fans

🔄 Fan Upgrades – Replaced existing units for better extraction

⚙️ Performance Testing – Verified 120% increase in airflow

💰 Budget Control – Ensured cost-effective execution

Result:

🌪 120% Airflow Increase – Enhanced fume extraction & air quality

🌍 Compliance Achieved – Met environmental & safety standards

👷♂️ Safer Work Environment – Reduced exposure to hazardous fumes

⚡ Optimized Operations – Improved booth efficiency

The project successfully enhanced safety, efficiency, and compliance while staying within budget. 🚀

Click to see Project details

📅 Project Timeline: Q2 2023 – Q4 2023

💰 Project Budget: USD 70,000

🎯 Objective: Enhance airflow capacity to improve air quality and operational safety

Objective:

This project aimed to increase the Acid Wash Booth’s airflow capacity by 100% to improve air quality, ensure worker safety, and comply with environmental regulations. The existing extraction system struggled to remove hazardous fumes, posing health risks and reducing operational efficiency.

By upgrading the extraction system, the plant achieved better ventilation, minimized fume accumulation, and created a safer work environment while ensuring compliance with workplace safety standards.

Upgrade Details:

The project involved engineering modifications to enhance the extraction system’s efficiency, including:

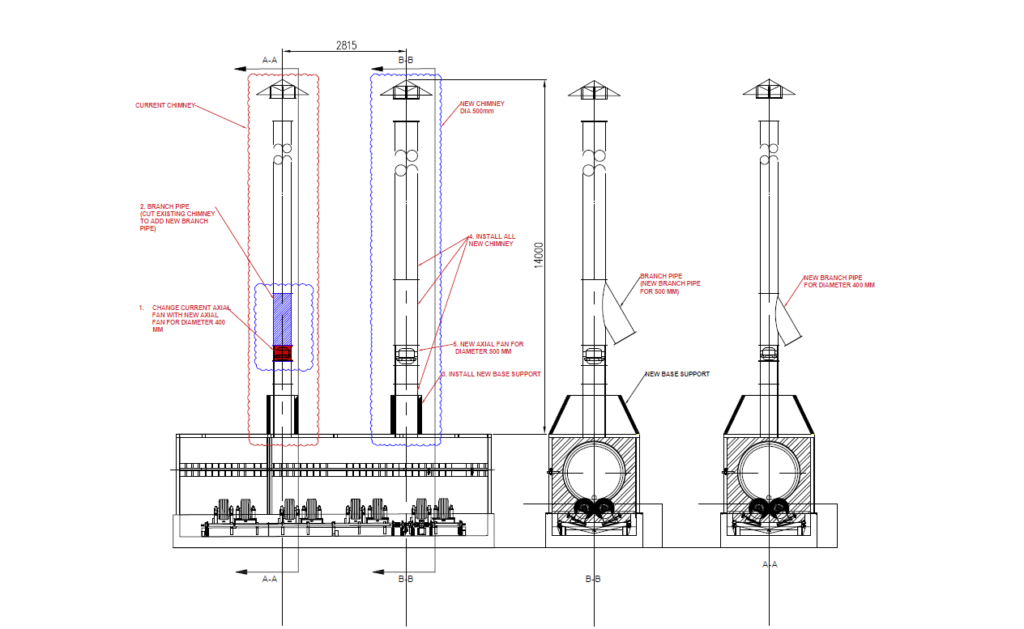

🔍 System Evaluation & Airflow Analysis – Assessed existing airflow limitations and designed an optimized extraction system.

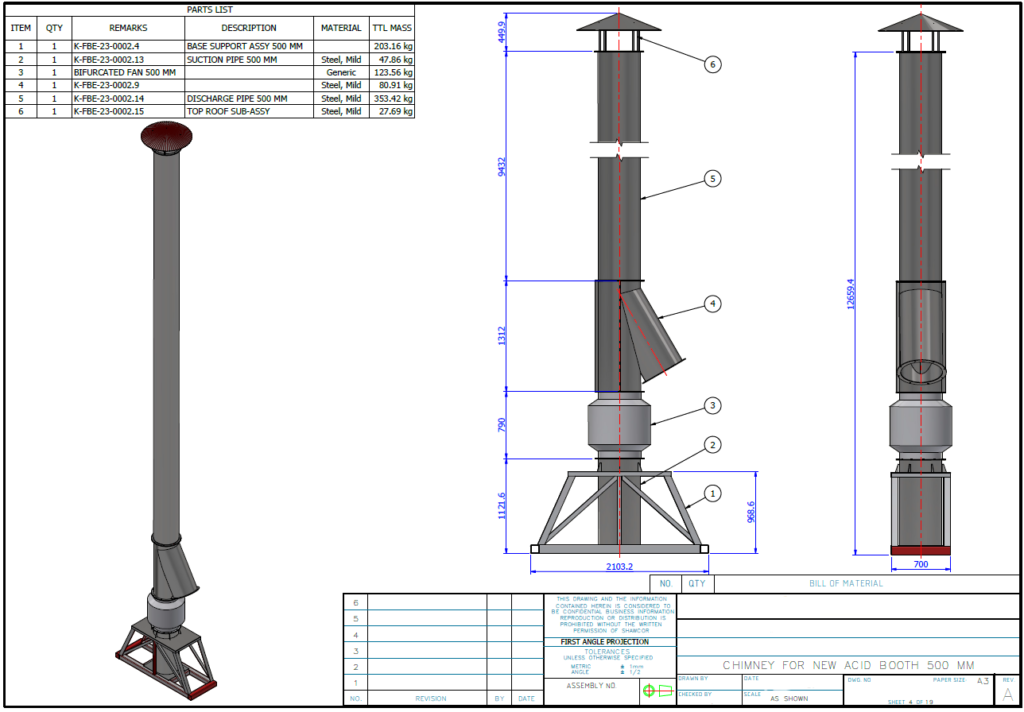

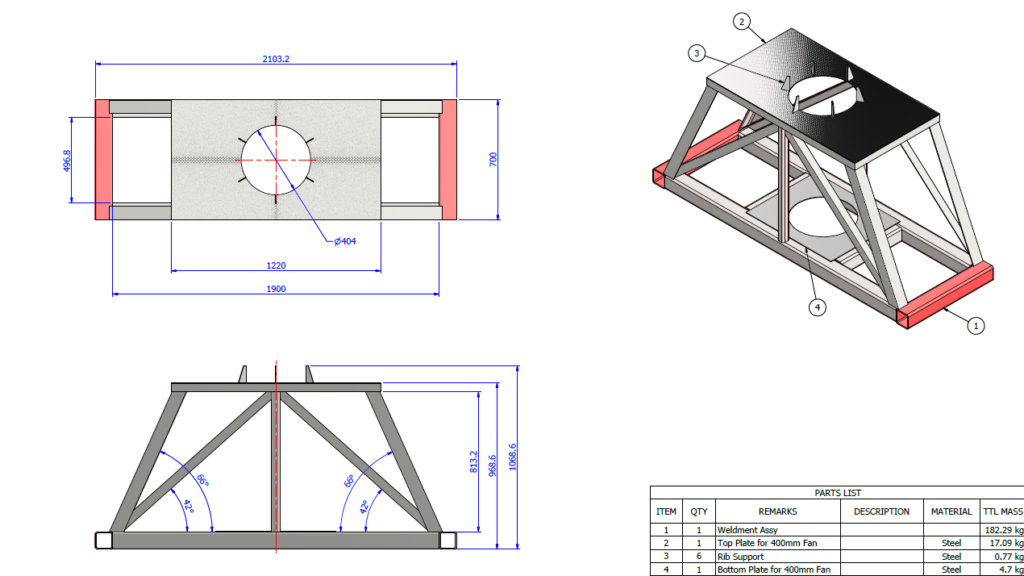

🏗 New Exhaust Chimney Installation – Added a high-performance chimney with advanced fans for improved fume removal.

🔄 Fan Replacement on Existing Chimney – Upgraded old fans with more efficient models to enhance airflow capacity.

⚙️ Performance Testing & Optimization – Conducted airflow tests to validate the 120% increase and ensure compliance with regulations.

Unlike a complete system overhaul, this upgrade focused on improving efficiency within the existing infrastructure while maximizing impact within the allocated budget.

Compliance & Safety:

The upgraded extraction system meets environmental and workplace safety regulations, providing key benefits:

✅ Regulatory Compliance – Ensures adherence to air quality and worker safety standards.

✅ Improved Ventilation – Enhances fume extraction, reducing exposure to hazardous chemicals.

✅ Safer Work Environment – Protects employees from harmful air contaminants.

✅ Operational Efficiency – Supports better process reliability and plant performance.

Operational Impact:

The improved extraction system provides significant operational advantages:

🌪 120% Airflow Increase – Ensures effective fume removal and ventilation.

👷♂️ Enhanced Worker Safety – Minimizes exposure to hazardous fumes.

⚡ Optimized Plant Performance – Improves booth efficiency and process reliability.

📈 Future Scalability – The upgraded system allows for potential future enhancements if needed.

Budget Management & Execution Strategy:

The project was completed within the USD 70,000 budget by strategically allocating resources:

💰 Cost-Effective Procurement – Sourced high-quality components for long-term efficiency.

🛠 Engineering & Installation – Workforce optimization for seamless implementation.

📊 Performance & Compliance Testing – Ensured regulatory alignment and effectiveness.

With no budget overruns, the project maximized safety, efficiency, and compliance while maintaining financial discipline.

Conclusion:

The Acid Wash Booth Extraction System Upgrade successfully improved workplace safety, enhanced ventilation, and increased operational efficiency. By focusing on targeted enhancements like chimney installation and fan upgrades, the project delivered a 120% airflow increase, ensuring a more effective and compliant extraction system.

This initiative strengthens long-term workplace safety, regulatory adherence, and plant efficiency, contributing to a healthier and more productive work environment.

🔧 Project Successfully Implemented – Enhancing Air Quality & Safety! 🚀